Saddle fittings are essential components in plumbing systems, providing a convenient and reliable way to tap into existing pipes for new connections or extensions. In this comprehensive guide, we’ll explore the features, benefits, applications, and considerations of saddle fittings, highlighting their significance in plumbing installations.

Types of Saddle

Key Features

-

Versatile Design

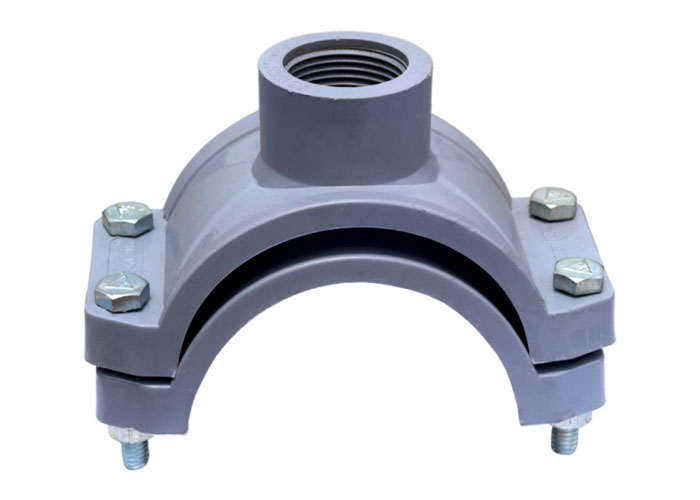

Saddle fittings come in various designs to suit different pipe materials, sizes, and applications. They typically consist of a saddle-shaped body with a securing mechanism, such as bolts or straps, to attach the fitting securely to the pipe.

-

Easy Installation

Saddle fittings are designed for easy installation, allowing plumbers to quickly and efficiently tap into existing pipes without the need for complex tools or extensive modifications. This saves time and labor costs during plumbing installations or repairs.

-

Durable Construction

Saddle fittings are constructed from robust materials such as brass, stainless steel, or PVC, ensuring durability and longevity in demanding plumbing environments. Their sturdy construction enables them to withstand high pressures and temperature fluctuations without compromising performance.

-

Leak-Proof Seal

Saddle fittings feature a sealing mechanism, such as rubber gaskets or O-rings, to create a watertight seal between the fitting and the pipe. This prevents leaks and ensures reliable performance in plumbing systems.

Applications of Saddle Fittings

-

Water Supply Systems

Installed in water distribution networks to create new connections for branch lines, faucets, or appliances.

-

Irrigation Systems

Utilized in agricultural and landscaping irrigation systems to tap into main supply lines for sprinkler heads or drip emitters.

-

HVAC Installations

Integrated into heating, ventilation, and air conditioning (HVAC) systems to create new connections for supply or return lines.

Benefits of Saddle Fittings

-

Versatility

Saddle fittings can be used in various plumbing applications, including water supply lines, irrigation systems, and HVAC installations. They provide a versatile solution for tapping into existing pipes to create new connections or branches.

-

Cost-Effectiveness

Saddle fittings are cost-effective alternatives to traditional pipe connection methods, such as cutting and welding. They eliminate the need for expensive tools and equipment, reducing installation costs and downtime.

-

Time Savings

Saddle fittings allow plumbers to complete pipe connections quickly and efficiently, minimizing project timelines and labor costs. This is particularly advantageous in emergency repair situations or time-sensitive installations.

-

Minimal Disruption

Saddle fittings require minimal disruption to existing piping systems, as they can be installed without cutting or altering the main pipe. This reduces the risk of damage to surrounding infrastructure and minimizes downtime during installation.

Considerations for Using Saddle Fittings

-

Pipe Material and Size

Ensure that the saddle fitting is compatible with the material and size of the existing pipe to ensure a proper fit and seal.

-

Installation Method

Follow manufacturer recommendations and industry best practices for installing saddle fittings to ensure proper alignment, sealing, and support.

-

Pressure and Temperature Ratings

Verify that the saddle fitting is rated for the operating pressure and temperature of the plumbing system to prevent failures or leaks.

-

Regulatory Compliance

Ensure that saddle fittings meet relevant industry standards and regulatory requirements for the specific application and installation location.